Standards for flooring underlay

The standards for evaluating quality

Following many years of preparation across numerous working groups at European level (CEN), but also within the EPLF association, official sets of rules and regulations defining specifications, requirements and test procedures for laminate and click vinyl flooring underlayment exist since 2013.

Before the introduction of such normatives, underlay is not described or standardised. There are legal requirements in some countries (e.g. Ü-mark), but these exclusively regulate fire behaviour and emissions and thus no performance parameters. SELIT was involved in this standardisation work, and was able to contribute to the fact that underlay is now covered with requirements which are of great importance for the entire floor structure. We give you an overview of the valid sets of rules and regulations and explain why the installation of underlay is necessary.

Why is an underlay necessary?

Floating flooring can only work if the underlay also is part of the overall flooring system. The underlay represents the connection between the floor and the substrate and should perform the following basic functions:

1. Ensure professional installation

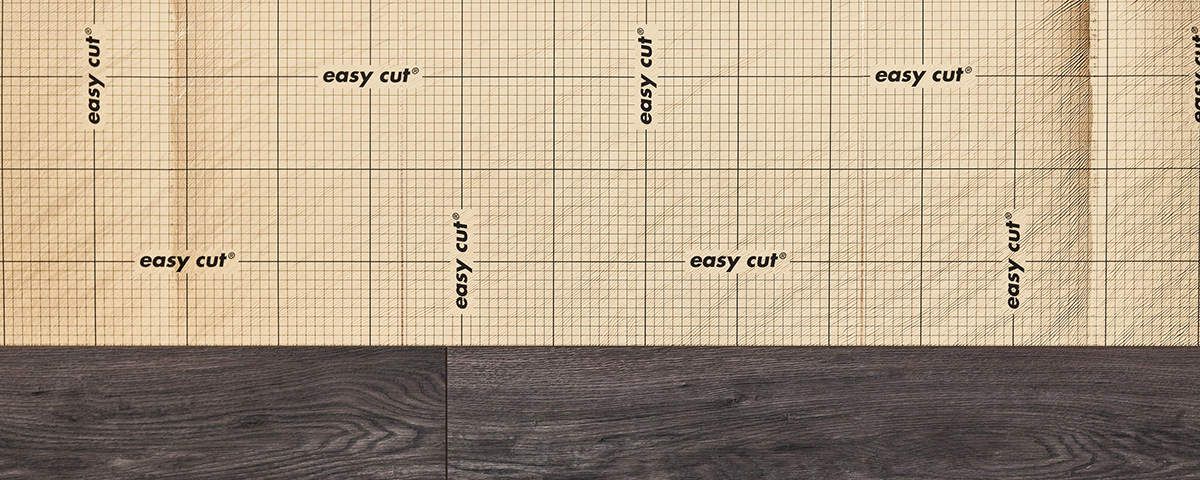

This includes compensating of unevenness and creating an installation surface that permits a floating installation.

2. Permanently protect the floor

Protecting the floor from everyday stress, for example, caused by footfall and falling objects, as well as protecting it against rising residual building moisture.

3. Improve the floor characteristics

In addition to reducing impact and impact sound, the underlay also influences thermal insulation and walking comfort.